Etanorm SYT

Thermal Oil / Hot Water Pumps

Feature

- Maximum Operating Reliability

- High energy efficiency

- Easy to service

- Robust Design

Applications

- Heat transfer system ( DIN 4754, VDI 3033 )

- Hot water circulation ( DIN 4752 )

| Technical Data * | Etanorm SYT / RSY | ||

|---|---|---|---|

| Thermal Oil | Hot Water | ||

| Max. Flow Rate | 1900 / 2280 | 1900 / 2280 | m3/h |

| Max. Head | 102 / 90 | 102 / 90 | m |

| Fluid Temperature | -30 to +350 | up to +180 | °C |

| Max. Operating Pressure | 16 | 16 | bar |

| * Values for 50 Hz/60 Hz | |||

Automation Options : PumpDrive, PumpExpert, Hyamaster, Hyatronic

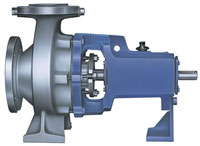

MEGA

Feature

- Flanges as per ASME (formerly ANSI) B 16.1 Class 125

- Modular construction, high interchangeability, fast delivery

- Versatile shaft sealing arrangement, Gland packing as a standard arrangement and option to use mechanical

Operating data

- Design : Horizontal back pull-out

- Pump size : DN 32 to 150 mm

- Capacity : up to 540 m3/hr

- Head : up to 100 m

- Discharge pr. : up to 16 bar

- Temperature : -30°C to +160°C

- Material : C. I., C. I. with Bronze internals,C.I. with S. S. internals

Application

- Water supply

- Drip irrigation

- Cooling water circulation

- Industrial washing machines

- Condensate handling

MEGA CHEM

Feature

- Flanges as per ASME B 16.5 Class 150 ( Drilling only )

- Modular construction, high interchangeability, fast delivery

- Versatile shaft sealing arrangement, Gland packing as a

- standard arrangement and option to use mechanical

- seal Process type design results in minimum downtime

Operating data

- Design : Horizontal back pull-out

- Pump size : DN 32 to 125 mm

- Capacity : up to 400 m3/hr

- Head : up to 100 m

- Discharge pr. : up to 24 bar

- Temperature : -30°C to +200°C

- Material : Cast Steel with various combinations in S. S., C. S.

Application

- Water treatment

- Organic & inorganic liquids

- Reverse osmosis

- Handling of pulp

- Solvent extraction

- Condensate handling

CPK

Feature

- Versatile due to broad range of materials

- Constant-level oiler

- Maintenance-friendly

- Long service life

- Low operating costs

Operating data

- Design : End suction process pump

- Pump size : DN 32 to 250 mm

- Capacity : up to 1200 m3/hr

- Head : up to 150 m

- Discharge Pr. : up to 25 bar

- Temperature : -70°C to +320°C

- Material : C. I., S. S., C. S., Cr. S.

Application

- Paper industry

- Organic/inorganic fluids

- Handling of sea water

- Sugar industry

- Food processing industry

- Petrochemical industry

- Chemical industry

MegaCPK

Standardised Chemical Pump

Feature

- In compliance with relevant standards

- High reliability and lower operating costs

- Energy Efficiency

- Lower investment costs

- Large range of variants for all applications

- The right size for each application

- Easy to Service

Application

For handling aggressive organic and inorganic fluids in

- Chemical Industry

- Petrochemical Industry

- Process Engineering

- Sugar Industry

- Biodiesel, bioethanol

- Fire-fighting systems / fire-fighting water

- Seawater desalination / reverse osmosis

- Condensate

- Hot Water

- Brine

- Steel Industry

- Heat Transfer Media

- Cleaning Agents

KWP

Feature

- Flanges to DIN 2535/16, 2532/10

- Interchangeable wear plate in various materials

- Two type of impellers for vide range of applications

- Axially adjusted bearing bracket with option of heavy

- bearing bracket

Operating data

- Design : End suction non-clog pump

- Pump size : DN 65 to 200 mm

- Capacity : up to 700 m3/hr

- Head : up to 100 m

- Temperature : -30°C to +250°C

- Material : C. I. with C.S. internals, C. S.

Application

- Sugar industry

- Paper industry

- Sewage & effluent

- treatment plant

- Chemical industry

- Handling of foodstuff

- Mining industry

APP

Feature

- Volute casing with low radial forces

- Externally adjustable wear plate to maintain the clearance between the impeller & wear plate

- Open impeller for handling of stock up to 8% consistency.

- Specially designed Spiral key for impeller locking

Operating data

- Design : End suction non-clog pump

- Pump size : DN 50 to 150 mm

- Capacity : up to 540 m3/hr

- Head : up to 105 m

- Discharge Pr. : up to 16 bar

- Temperature : -100°C to +180°C

- Material : Cast Iron, S. S. 2324

Application

- Handling of paper pulp

- Process industries

- Handling of foodstuff

WK / WL / WKFI / WKS

Feature

- Flanges to DIN standard

- Normal design for temperature up to 105°C

- For temperature above 105°C; Hot Water Design with cooled stuffing box is available

- Axial thrust is balanced by balancing holes on impeller shroud or the balancing and counter balancing disc

Operating data

- Design : Multi-stage high pressure pump

- Pump size : DN 40 to 150 mm

- Capacity : up to 630 m3/hr

- Head : up to 780 m

- Discharge Pr. : up to 63 bar

- Temperature : -10°C to 230°C

- Material : C. I., C. I. with Bronze internals C. S., CA6NM

Application

- Boiler feed applications

- Condensate extraction

- Fire fighting

- Irrigation

- Sprinklers

movi

Feature

- Normal design for temperature up to 110°C

- Hot water design for temperature from 110°C to 140°C

- Nozzles can be turned by 90° for easy installations

- Various combination of impellers for wide performance

Operating data

- Design : Multi-stage high pressure pump

- Pump size : DN 32 mm

- Capacity : up to 18 m3/hr

- Head : up to 368 m

- Discharge Pr. : up to 40 bar

- Temperature : -10°C to 140°C

- Material : Cast Iron, C. I. with Bronze internals

Application

- General water supply

- Sprinklers

- Irrigation

- Booster plants

- Fire fighting

movi tech vcf

Construction & applications

Multi-stage, vertical inline high-pressure centrifugal pumps in ring-section design. suitable for general water supply, sprinkling, irrigation and pressure boosting systems, warn water, hot water and colling water re-circulation, boiler feed systems, domestic water supply systems and washing plants.

Operating data

- Pump size : DN 25 to 50 mm

- Capacity : Q up to 24 m/hr.

- Head : H up to 228 m

- Discharge pressure : p up to 25 bar

- Temperature : t -15 ti 120 C

- Speed : n up to 3600 rpm

HDA

Feature

- Flanges to DIN/ASME/BS

- Axial thrust balancing by balancing disc

- Stage sealing by "O" rings

- Lift off device with segmental thrust bearing enables high no. of start-stops

- Higher interchangeability

- Option of cooled stuffing box is available

Operating data

- Design : Multi-stage ring-section pump

- Pump size : DN 40 to 150 mm

- Capacity : up to 575 m3/hr

- Head : up to 1750 m

- Discharge Pr. : up to 230 bar

- Temperature : up to 230°C

- Material : C.I., WCB, CA6NM

Application

- Handling boiler feed water

- Descaling plants

- Coke cutting

- Pressure generation for

- hydraulic press

- Municipal water supply

RPH

Feature

- Pump designed to API 610 10th edition

- Specially designed impeller for low NPSHr

- Finned bearing bracket with option to use fan for cooling

- Optional triple bearing assembly for high suction pressure

- Seal chamber designed to API 682

Operating data

- Design : End suction process pump

- Pump size : DN 25 to 250 mm

- Capacity : up to 1500 m3/hr

- Head : up to 270 m

- Discharge Pr. : up to 51 bar

- Temperature : up to 450°C

- Material : Stainless Steel, Chrome Steel

Application

- Handling of paper pulp

- Process industries

- Handling of foodstuff

krtu / krte

Feature

- Stationary & portable executions are available

- Three types of impeller for handling variety of liquids

- Safe operation due to resin filled cables gland

- Bi-directional mechanical seal ensures long service life

- Temperature sensors protect motor from overheating

- Can handle solids up to 100 mm diameter

Operating data

- Design : Submersible motor pump

- Pump size : DN 65 and 200 mm

- Capacity : up to 100 m/hr.

- Head : up to 100 m

- Motor power : up to 9.5 kW

- Temperature : up -30 to 250°C

- Material : Cast Iron

Application

- Water treatment

- Hotels

- Water transfer e.g. storm water

- Food processing industry

- Paper industry

- Sugar industry

AMA PORTER

Feature

- Water treatment

- Hotels

- Water transfer e.g. storm water

- Food processing industry

- Paper industry

- Sugar industry

Operating data

- Design : Monobloc pumpset

- Pump size : DN 50 mm

- Capacity : up to 29 m3/hr

- Head : up to 16 m

- Motor rating : up to 1.5 kW

- Temperature : up to 40°C

- Material : C. I.

Application

- Pumping of surface water

- Pumping of rain water

- Waste water containing solids

- Drainage of sumps liable to flood

SubmERsible Motor pumps

Feature

- High efficiency

- Available in radial & mixed flow impeller designs

- Low power consumption

- Easily serviceable

- Environment friendly

Operating data

- Design : Submersible Motor Pump

- Pump size : 150 mm to 350 mm

- Type series : UQD, BPD, BPH, UPH, BPN, BPVs, BQTs

- Capacity : up to 900 m3/hr

- Head : up to 300 m

- Motor power : up to 110 kW

Application

- Agriculture

- Sprinkler / Drip irrigation

- Drinking water supply

- Mine de-watering

- Commercial complexes

- Sea water desalination

- Pressure boosting

Monosub R

Construction & applications

Single stage, monobloc, open-well submersible pumps. suitable for agriculture, drinking water supply, fountains, buildings, farm houses etc. available in single and three phase modles.

Operating data

- Pumps size : DN 25 to 100 mm

- Capacity : Q up to 120 m/hr.

- Head : H up to 60 m

- Motor rating : P up to 0.5 to 10 hp

ETALINE

KSB Etaline – the flexible in-line pump for a wide range of applications

Etaline can be installed horizontally or vertically directly in the pipeline and is available in 22 different sizes. A wide range of materials enables the pump to handle the most diverse types of fluids. But best of all, the new in-line pumps from this series are remarkably efficient: when combined with the high-efficiency KSB SuPremE® motor and the PumpDrive variable speed system, KSB Etaline is the world's most efficient magnet-less pump set.

Your benefits at a glance:

- Flange connections to EN, optionally drilled to ASME

- Standardised mechanical seal from codes 6 to 11 available as standard

- Replaceable casing wear rings

- Low vibration levels and very smooth running

- Confined casing gasket

- Designed for operating pressures of up to 16 bar

- Also available in twin-pump design Etaline Z – for maximum operating reliability

Etaline: the ideal choice for use in complex buildings

Alongside industrial engineering applications, KSB's Etaline is an ideal choice for heating, ventilation and air-conditioning systems in complex buildings. The in-line pump is in great demand – especially in high-rise buildings and skyscrapers – as it takes up considerably less of the expensive space that is required for traditional long-coupled designs.

ETABLOCK

KSB Etabloc: the compact close-coupled pump for small spaces

Etabloc comes into its own in situations where every centimetre counts: with pump and motor connected in one compact unit the close-coupled pump features an extremely space-saving design that is perfect when things get tight. And all this without sacrificing excellent efficiency!

Your benefits at a glance:

- High level of energy efficiency with the IE4-class KSB SuPremE® motor (IE4 according IEC (CD) 60034-30 Ed. 2)

- Use with KSB's PumpDrive for maximum energy efficiency and complete operational transparency

- Pump without separate coupling – aligning is not required

- Wide variety of materials for many applications available as standard

- Additional pump sizes for small flow rates

- Simplified dismantling and reassembly thanks to enlarged seal chamber

- Power range up to 110 kW (50/60 Hz) and 6-pole operation (0.55 to 15 kW) possible

The perfect match: Etabloc with PumpMeter, PumpDrive and KSB SuPremE® motor KSB's Etabloc exceeds the requirements of the ErP Directive applicable to standardised water pumps from 2015. The excellent values achieved by KSB's Etabloc can be improved even further by using the pump in combination with the Pump Drive variable speed system – and all of this comes with complete operational transparency. With the KSB SuPremE® motor which already achieves the IE4 (according IEC (CD) 60034-30 Ed. 2) energy efficiency level today, this close-coupled pump is far ahead of its time.

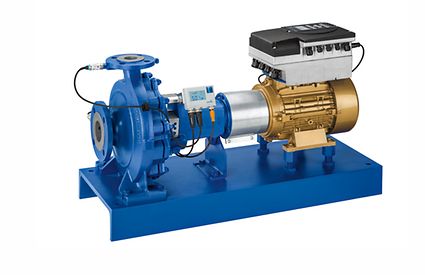

ETANORM

KSB Etanorm: performance by design meets excellent efficiency

Etanorm is the world's best-selling standardised water pump. But that hasn't stopped KSB making improvements: optimised hydraulic systems save up to 7,000 kW/h of energy a year – which means cost savings of several thousand euros per pump and markedly reduced CO2 emissions.

Your benefits at a glance:

- Significant energy savings and improved efficiency

- More than ready for ErP 2015

- Confined casing gasket for varying operating conditions

- Additional sizes for small flow rates

- Enlarged seal chamber and forcing screws between casing cover and bearing bracket for straightforward dismantling/reassembly

- Impeller diameter is trimmed to optimum operating point as standard

Etanorm combined with PumpDrive, PumpMeter and a KSB SuPremE® motor

A high-efficiency motor such as the KSB SuPremE®, variable speed operation with PumpDrive and the intelligent pump monitoring system PumpMeter make even more energy savings possible with Etanorm.

KSB SuPremE® motors already satisfy the efficiency requirements for electric motors according to the applicable ErP regulation (IE4 to IEC (CD) 60034-30 Ed. 2) and are, therefore, well ahead of their time. Thanks to the use of non-critical, sustainable materials, these motors are extremely robust and durable.

The PumpDrive variable speed system facilitates even more efficiency gains with KSB Etanorm. The principle: the PumpDrive frequency inverter allows quick, precise and continuously variable speed adjustment of the pump's drive to the actual requirements.