MEGA

Feature

- Flanges as per ASME (formerly ANSI) B 16.1 Class 125

- Modular construction, high interchangeability, fast delivery

- Versatile shaft sealing arrangement, Gland packing as a standard arrangement and option to use mechanical

Operating data

- Design : Horizontal back pull-out

- Pump size : DN 32 to 150 mm

- Capacity : up to 540 m3/hr

- Head : up to 100 m

- Discharge pr. : up to 16 bar

- Temperature : -30°C to +160°C

- Material : C. I., C. I. with Bronze internals,C.I. with S. S. internals

Application

- Water supply

- Drip irrigation

- Cooling water circulation

- Industrial washing machines

- Condensate handling

MEGA CHEM

Feature

- Flanges as per ASME B 16.5 Class 150 ( Drilling only )

- Modular construction, high interchangeability, fast delivery

- Versatile shaft sealing arrangement, Gland packing as a

- standard arrangement and option to use mechanical

- seal Process type design results in minimum downtime

Operating data

- Design : Horizontal back pull-out

- Pump size : DN 32 to 125 mm

- Capacity : up to 400 m3/hr

- Head : up to 100 m

- Discharge pr. : up to 24 bar

- Temperature : -30°C to +200°C

- Material : Cast Steel with various combinations in S. S., C. S.

Application

- Water treatment

- Organic & inorganic liquids

- Reverse osmosis

- Handling of pulp

- Solvent extraction

- Condensate handling

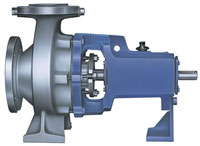

CPK

Feature

- Versatile due to broad range of materials

- Constant-level oiler

- Maintenance-friendly

- Long service life

- Low operating costs

Operating data

- Design : End suction process pump

- Pump size : DN 32 to 250 mm

- Capacity : up to 1200 m3/hr

- Head : up to 150 m

- Discharge Pr. : up to 25 bar

- Temperature : -70°C to +320°C

- Material : C. I., S. S., C. S., Cr. S.

Application

- Paper industry

- Organic/inorganic fluids

- Handling of sea water

- Sugar industry

- Food processing industry

- Petrochemical industry

- Chemical industry

MegaCPK

Standardised Chemical Pump

Feature

- In compliance with relevant standards

- High reliability and lower operating costs

- Energy Efficiency

- Lower investment costs

- Large range of variants for all applications

- The right size for each application

- Easy to Service

Application

For handling aggressive organic and inorganic fluids in

- Chemical Industry

- Petrochemical Industry

- Process Engineering

- Sugar Industry

- Biodiesel, bioethanol

- Fire-fighting systems / fire-fighting water

- Seawater desalination / reverse osmosis

- Condensate

- Hot Water

- Brine

- Steel Industry

- Heat Transfer Media

- Cleaning Agents

KWP

Feature

- Flanges to DIN 2535/16, 2532/10

- Interchangeable wear plate in various materials

- Two type of impellers for vide range of applications

- Axially adjusted bearing bracket with option of heavy

- bearing bracket

Operating data

- Design : End suction non-clog pump

- Pump size : DN 65 to 200 mm

- Capacity : up to 700 m3/hr

- Head : up to 100 m

- Temperature : -30°C to +250°C

- Material : C. I. with C.S. internals, C. S.

Application

- Sugar industry

- Paper industry

- Sewage & effluent

- treatment plant

- Chemical industry

- Handling of foodstuff

- Mining industry

APP

Feature

- Volute casing with low radial forces

- Externally adjustable wear plate to maintain the clearance between the impeller & wear plate

- Open impeller for handling of stock up to 8% consistency.

- Specially designed Spiral key for impeller locking

Operating data

- Design : End suction non-clog pump

- Pump size : DN 50 to 150 mm

- Capacity : up to 540 m3/hr

- Head : up to 105 m

- Discharge Pr. : up to 16 bar

- Temperature : -100°C to +180°C

- Material : Cast Iron, S. S. 2324

Application

- Handling of paper pulp

- Process industries

- Handling of foodstuff

WK / WL / WKFI / WKS

Feature

- Flanges to DIN standard

- Normal design for temperature up to 105°C

- For temperature above 105°C; Hot Water Design with cooled stuffing box is available

- Axial thrust is balanced by balancing holes on impeller shroud or the balancing and counter balancing disc

Operating data

- Design : Multi-stage high pressure pump

- Pump size : DN 40 to 150 mm

- Capacity : up to 630 m3/hr

- Head : up to 780 m

- Discharge Pr. : up to 63 bar

- Temperature : -10°C to 230°C

- Material : C. I., C. I. with Bronze internals C. S., CA6NM

Application

- Boiler feed applications

- Condensate extraction

- Fire fighting

- Irrigation

- Sprinklers

movi

Feature

- Normal design for temperature up to 110°C

- Hot water design for temperature from 110°C to 140°C

- Nozzles can be turned by 90° for easy installations

- Various combination of impellers for wide performance

Operating data

- Design : Multi-stage high pressure pump

- Pump size : DN 32 mm

- Capacity : up to 18 m3/hr

- Head : up to 368 m

- Discharge Pr. : up to 40 bar

- Temperature : -10°C to 140°C

- Material : Cast Iron, C. I. with Bronze internals

Application

- General water supply

- Sprinklers

- Irrigation

- Booster plants

- Fire fighting

movi tech vcf

Construction & applications

Multi-stage, vertical inline high-pressure centrifugal pumps in ring-section design. suitable for general water supply, sprinkling, irrigation and pressure boosting systems, warn water, hot water and colling water re-circulation, boiler feed systems, domestic water supply systems and washing plants.

Operating data

- Pump size : DN 25 to 50 mm

- Capacity : Q up to 24 m/hr.

- Head : H up to 228 m

- Discharge pressure : p up to 25 bar

- Temperature : t -15 ti 120 C

- Speed : n up to 3600 rpm

HDA

Feature

- Flanges to DIN/ASME/BS

- Axial thrust balancing by balancing disc

- Stage sealing by "O" rings

- Lift off device with segmental thrust bearing enables high no. of start-stops

- Higher interchangeability

- Option of cooled stuffing box is available

Operating data

- Design : Multi-stage ring-section pump

- Pump size : DN 40 to 150 mm

- Capacity : up to 575 m3/hr

- Head : up to 1750 m

- Discharge Pr. : up to 230 bar

- Temperature : up to 230°C

- Material : C.I., WCB, CA6NM

Application

- Handling boiler feed water

- Descaling plants

- Coke cutting

- Pressure generation for

- hydraulic press

- Municipal water supply

RPH

Feature

- Pump designed to API 610 10th edition

- Specially designed impeller for low NPSHr

- Finned bearing bracket with option to use fan for cooling

- Optional triple bearing assembly for high suction pressure

- Seal chamber designed to API 682

Operating data

- Design : End suction process pump

- Pump size : DN 25 to 250 mm

- Capacity : up to 1500 m3/hr

- Head : up to 270 m

- Discharge Pr. : up to 51 bar

- Temperature : up to 450°C

- Material : Stainless Steel, Chrome Steel

Application

- Handling of paper pulp

- Process industries

- Handling of foodstuff

krtu / krte

Feature

- Stationary & portable executions are available

- Three types of impeller for handling variety of liquids

- Safe operation due to resin filled cables gland

- Bi-directional mechanical seal ensures long service life

- Temperature sensors protect motor from overheating

- Can handle solids up to 100 mm diameter

Operating data

- Design : Submersible motor pump

- Pump size : DN 65 and 200 mm

- Capacity : up to 100 m/hr.

- Head : up to 100 m

- Motor power : up to 9.5 kW

- Temperature : up -30 to 250°C

- Material : Cast Iron

Application

- Water treatment

- Hotels

- Water transfer e.g. storm water

- Food processing industry

- Paper industry

- Sugar industry

AMA PORTER

Feature

- Water treatment

- Hotels

- Water transfer e.g. storm water

- Food processing industry

- Paper industry

- Sugar industry

Operating data

- Design : Monobloc pumpset

- Pump size : DN 50 mm

- Capacity : up to 29 m3/hr

- Head : up to 16 m

- Motor rating : up to 1.5 kW

- Temperature : up to 40°C

- Material : C. I.

Application

- Pumping of surface water

- Pumping of rain water

- Waste water containing solids

- Drainage of sumps liable to flood

SubmERsible Motor pumps

Feature

- High efficiency

- Available in radial & mixed flow impeller designs

- Low power consumption

- Easily serviceable

- Environment friendly

Operating data

- Design : Submersible Motor Pump

- Pump size : 150 mm to 350 mm

- Type series : UQD, BPD, BPH, UPH, BPN, BPVs, BQTs

- Capacity : up to 900 m3/hr

- Head : up to 300 m

- Motor power : up to 110 kW

Application

- Agriculture

- Sprinkler / Drip irrigation

- Drinking water supply

- Mine de-watering

- Commercial complexes

- Sea water desalination

- Pressure boosting

Monosub R

Construction & applications

Single stage, monobloc, open-well submersible pumps. suitable for agriculture, drinking water supply, fountains, buildings, farm houses etc. available in single and three phase modles.

Operating data

- Pumps size : DN 25 to 100 mm

- Capacity : Q up to 120 m/hr.

- Head : H up to 60 m

- Motor rating : P up to 0.5 to 10 hp